TRADING

Steel

Billets

Long semi-finished steel product with square section. The billets are used to make a multitude of products. They are rolled or forged into shapes such as reinforced concrete reinforcing bars, commercial bars, structural profiles or wire rod.

Slabs

Steel slabs are hot-rolled from an ingot or strand cast. They are wide and rectangular in shape.

Hot Rolled Coils And Sheets

Hot rolled coil is rolled on a hot strip mill from slabs. It can be found on the market in coil or sheet form and is further processed into finished products by the manufacturer. Hot rolled coil is typically 2-25mm thick and up to 2,250mm wide.

Cold Rolled Coils

Cold rolled steel is a ‘flat’ steel product. The material is manufactured from hot rolled steel, the thickness of which is further reduced on a strip mill without the use of heat. The resulting thinner and flatter material is known as cold rolled steel. Typical thickness is from 0.15 to 3 mm. Typical width is

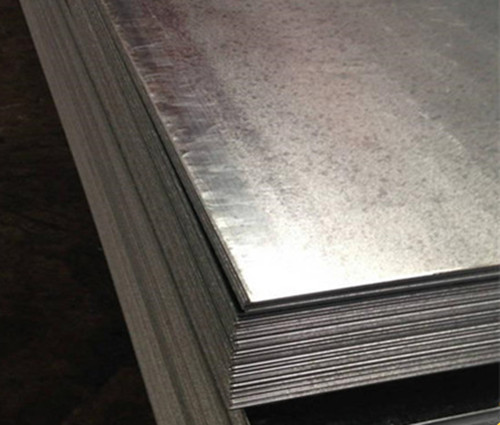

Galvanized Coils

Obtained by passing cold rolled coil through a molten zinc bath, in order to coat the steel with a thin layer of zinc to provide corrosion resistance. Hot dipped galvanized coil can be found on the market in coil or in sheets and is further processed into finished products by the manufacturer. Typical thickness is from 0.3 to 3 mm. Typical width is from 600 to 2,100 mm.

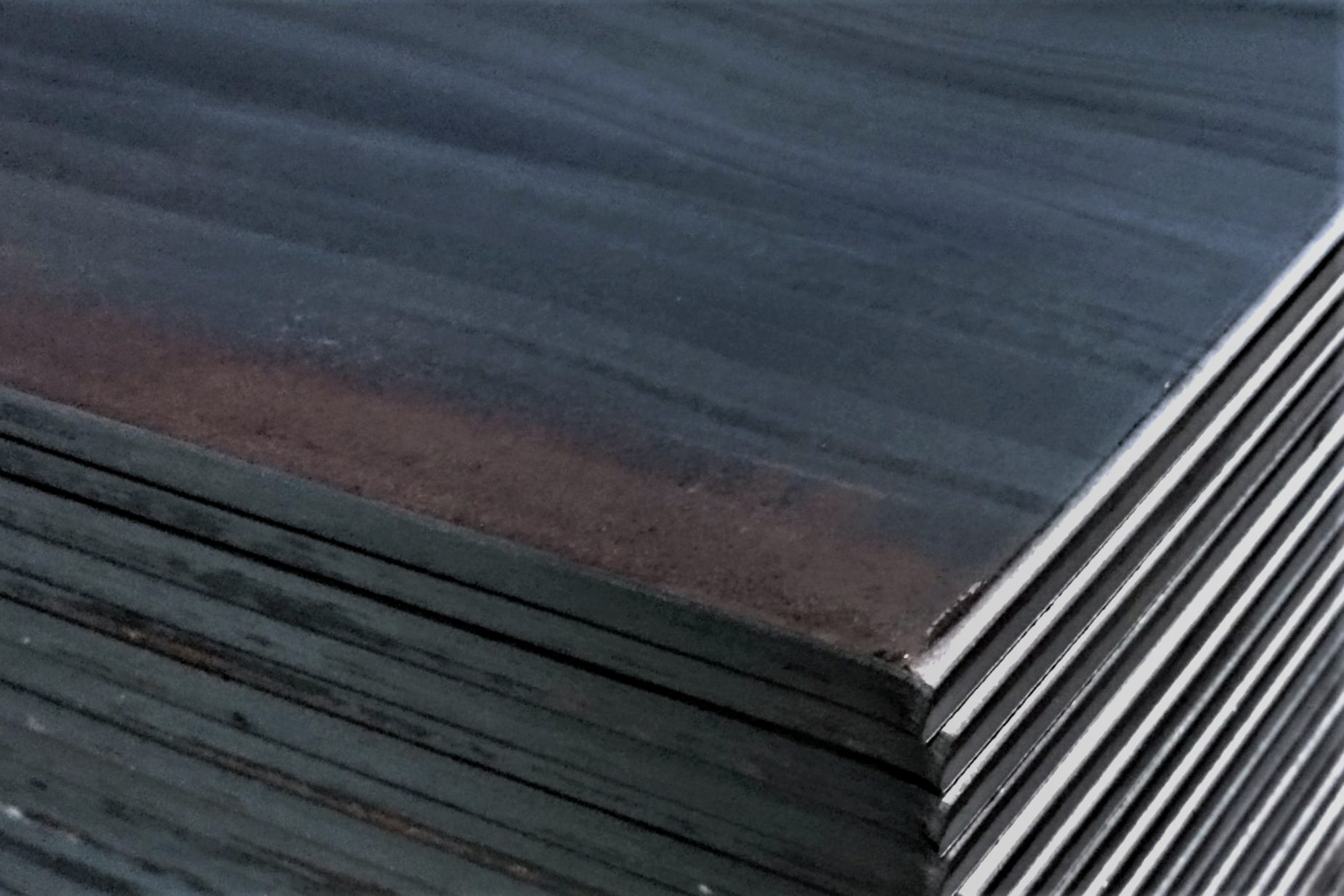

Hot Rolled Plate

Hot rolled plate is produced by hot rolling a steel slab to form a plate. Typical thickness is between 2 to 20mm and maximum width is 1860 mm.

Tin Plates

Steel slabs are hot-rolled from an ingot or strand cast. They are wide and rectangular in shape.

D-bars

D-bars is formed from a steel billet, normally having surface deformations for use in reinforcing concrete. The bar can be produced in straight lengths as well as coiled.

Structured Profiles

Heavy or structural sections are steel products such as beams or columns which are usually formed with a specific cross section shape e.g. H, I or U.

Wire Rod

Hot rolled from steel billet, wire rod is delivered as coil, most commonly at 5.5mm dia, but in sizes up to 60mm dia. Close control of final cooling is a critical part of production. The most important characteristic for determining a rod’s end use is its drawability; the extent to which the rod’s diameter can be reduced during the drawing process.

Seamless Pipes

Seamless tubes are made by rolling a preheated billet between offset rolls to create a tube shell. The tube shell is then elongated in a multi-stand rolling mill (with a mandrel) to achieve the desired wall thickness and a limited range of diameters. Tube diameter can also be achieved with a sizing collar, but for significant diameter changes the tube is reheated and passed through a stretch-reducing mill.

Welded Tubes

Welded tubes are made from hot rolled or cold reduced strip, sheet or plate. Welded tube includes hollow sections, black and galvanised gas/water pipe, scaffolding tube and large diameter pipe. Small and medium diameters are produced in continuous, multiple-roll mills that progressively bend incoming, unheated strip into a circular cross-section prior to welding along the longitudinal seam. Tube may subsequently be cold-drawn through dies to achieve precise dimensions and finish. Large diameters (400-1,600mm) are made from discrete plate which is welded in an “O” shape before being mechanically or hydraulically expanded. Spiral welded tube/pipe is available in diameters up to 2,500mm.